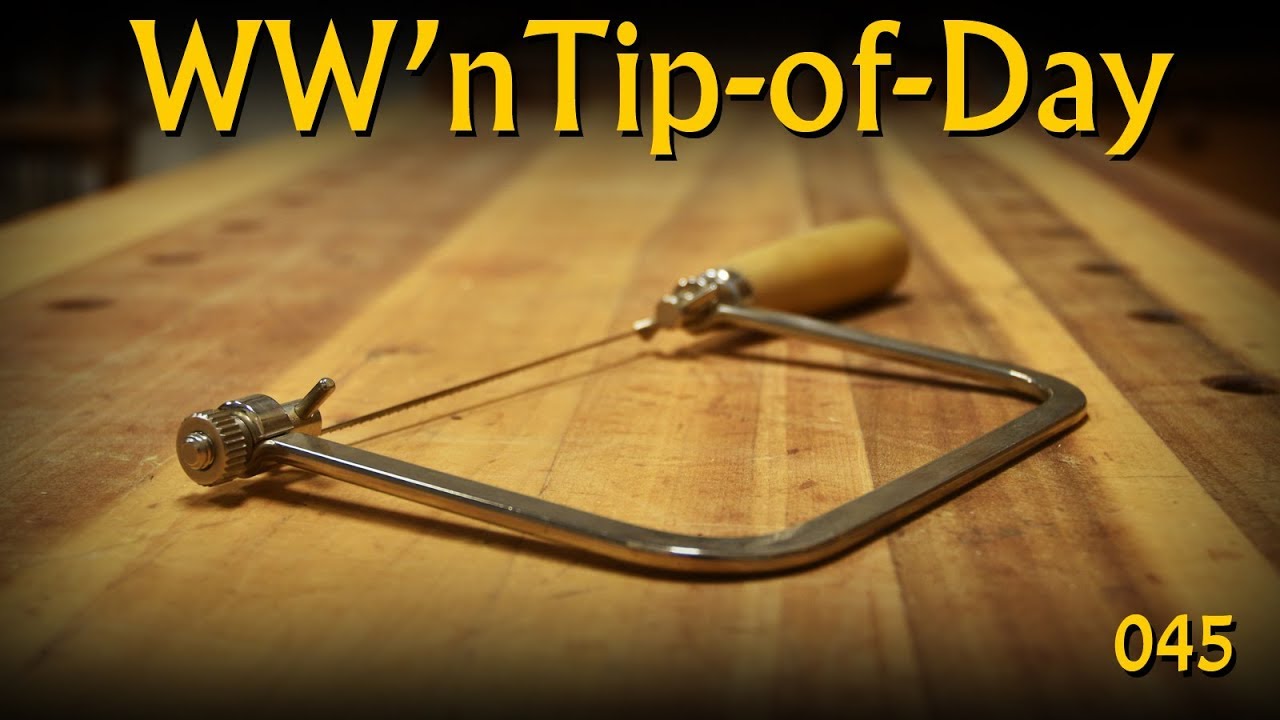

What's a fitting saw?

A copingsaw is an excellent handsaw type that is used to cut woodwork or carpentry's internal cuts. It can also make straight cuts that are angled. It's used to cut angles, particularly to make mitre joints or the rabbets needed to make a wooden piece more sturdy. Although it isn't as fast as a full-scale saw, it can make very straight and straight cuts Check over here when it comes to making corners. This type of saw is ideal to use for handwork.

This saw is able to make straight edges. In contrast to the bow saw that is typically best suited to cutting small pieces of metal or wood however, this saw is able to cut larger chunks of metal and wood. The reason is its ability to accommodate straight cuts and angles cuts. A good example of this is the way in which the old baseball bats were produced. To alter the angle of your blade from straight to curvy, you'll need an end that is normal and slightly bent.

Unlike a straight edge, the coping can be adjusted to cut at an angle of 90 degrees. The adjustment of the handle and blade size can accomplish this. It is done by loosening the screws in the handle. It is accomplished by opening the saw handle. Then, you can place your finger underneath the handle and observe whether the angle changes. If you find that it is, you can adjust the handle to suit your needs.

No matter what kind of coping tool, curves and corners are made using them. To make this happen, there are two things that you must think about. First, the width of the blade you want to use. And, secondly, the distance between the center and the wall of the blade. This will help you to cut in the case that your radius is smaller than the one you need. Teeth that are curly will help in cutting.

The laws are in many ways comparable to tablesaws. They differ in that they are able to cut thicker materials than tablesaws and thus more difficult to work with, just like metals. They can also be used to make precise woodwork as well as other work that requires precision.

This saw is employed for many different purposes for DIY markets. First, they are used to make intricate cuts that are shaped in different ways. The second is to create small intricate cuts into various shapes. The third can be used to make cuts in thin materials that are too bulky to be cut by a conventional wood coping saw.

The saw's blade is what cuts the material. It is the most crucial aspect, because should it not function properly and properly, you will not get the perfect cut. The saws have some designs which allow you to change your blade to an alternative design. Some allow reverse or forward motion. Some will still have two blades, which will allow for crosses or angled cuts. This is important because some wood is soft and require to be cut at an angle.

These saws are simple and easy to use in appearance. There are no intricate metal cutting bits or sharpening angles. The primary function of these tools is to speedily and accurately cut different shapes into various sizes. You can use them to do woodworking or metalworking. There are designs with a finger guard to make it easier to cut angled cuts.